Vertical indoor farming enables crops to grow all year round. It requires less space and promises to reduce water, fertiliser, and pesticide use, thus protecting both climate and soil. But this must be part of a larger transformation of food systems.

With rapid urbanisation, the idea of soilless crop cultivation is gaining traction. Vertical indoor farming, a prominent approach in controlled environment agriculture (CEA), enables the effective cultivation of lettuce, leafy green vegetables, and herbs in closed buildings. Warehouses or specially designed buildings are filled with multi-tiered structures that resemble shelves or racks. These vertical layers, sometimes stretching from floor to ceiling, are lined with rows of plants growing in carefully controlled environments. Instead of soil, the plants are rooted in nutrient-rich water solutions, which are circulated through the system to provide the essential minerals and hydration the plants need to grow. Alternatively, the roots are suspended in air or a growing medium like coconut fibre or perlite, with the nutrient solution delivered directly to them.

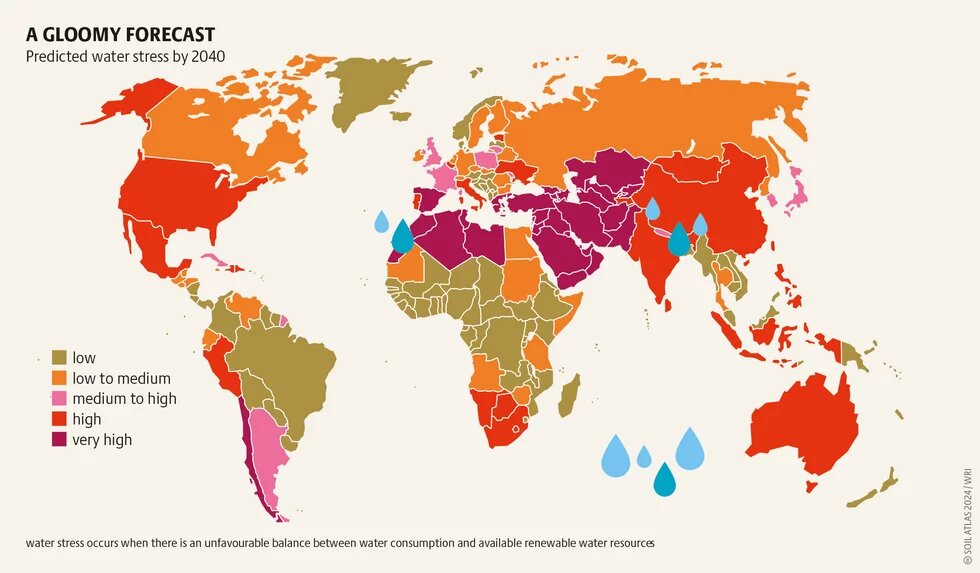

The closed systems ensure that no or few pollutants, such as fertiliser runoff or pesticide residues, escape from indoor farms into the soil or groundwater. Because the plants are exposed to fewer pathogens, pesticide use is also greatly reduced. Computers control LED lighting, water, temperature, and nutrient levels, enabling the plants to grow quickly with yields up to ten times higher than those achieved using conventional production methods. Such methods also save water. At Nordic Harvest, Europe’s largest vertical farm in Denmark, the plants require 95 percent less water thanks to a recycling system. This low water requirement is a major benefit in the context of the climate crisis, and the reduced need for space also relieves the burden on land and soils. In recent years, vertical indoor farming has experienced a boom, with supermarket chains, such as Walmart based in the United States or Lidl and Rewe based in Germany, investing billions.

However, vertical farming uses significant amounts of energy, making it uneconomical due to high energy prices. As of 2022, several North American and European start-ups exited the market due to high electricity and gas costs. In the Global North, a high-tech system that creates the perfect growing conditions from lighting and temperature to water supply costs at least 300 US dollars per square metres. A study conducted in Arizona found that hydroponic lettuce required 82 times more energy than conventional production methods, though milder climates reduce this need.

Moreover, if that energy comes from fossil energy sources, indoor farms are responsible for higher emissions of carbon dioxide. A 2022 study compared emissions from outdoor cultivation with those from a vertical farm in the Netherlands. It found that growing vegetables in a vertical facility produced up to 16 times more emissions than field cultivation. Higher energy and labour costs pushed production costs up, resulting in higher prices for vertically produced food. Even so, vertical farms may be economical in densely populated cities, such as Hong Kong or New York, where land prices are very high. Proponents argue that shorter transport routes and the elimination of intermediaries can save as much as 60 percent of the overall costs. However, even where cost-efficient models exist, technical expertise and a continuous supply of water and energy are essential.

A look at the types of crops grown shows that soilless agriculture can make an important contribution to the provision of micronutrients and can help avoid harmful pesticide residues. Yet, it cannot replace the field cultivation of potatoes, rice, or other cereals – crops that have high energy requirements and need more macronutrients than lettuce. In theory, vertical farms could produce wheat under optimal conditions. One study estimated that a 10-storey vertical farm built on an area of one hectare could produce between 700 and 1,940 tonnes of wheat a year. This is 220 to 600 times the average global wheat yield of 3.2 tonnes per hectare. However, production costs might be enormous. In 2020, an art installation calculated the price of wheat grown in a closed, one-square-metre space with an artificial supply of light, water, heat, and nutrients at 200 euros per kilogram.

Hydroponic systems in controlled environments have also been tested in informal urban settlements in the Global South to analyse their potential to contribute to food security through the local production of selected vegetables. Several projects run in Nairobi, Kenya achieved high levels of local participation resulting in significant knowledge transfer. These projects highlighted the specific functions of CEA, such as adaptation to climate change and enhancing the production of nutritious food for urban communities in challenging environments with scarce resources.

Critics argue that CEA approaches such as vertical indoor farming, while interesting, cannot meet global agricultural challenges. Up until now, vertical farming seems to be suited only to water-rich fruits and leafy vegetables, which are low in calories despite being important for a balanced diet. In order to reduce the land consumption for agricultural production, agriculture must be restructured to create a more just and

sustainable food system. In Europe, over 63 percent of arable land is currently used to grow fodder, highlighting the need for change so that land is used more efficiently to provide healthy food for people, while saving natural resources. Nonetheless, soil depletion and the climate crisis may make soilless farming indispensable in the long run.